Ozibuthe be-Neodymium kuqiniswe ngengubo evikelayo

Ozibuthe be-Neodymium bayaphawuleka ngamandla abo angavamile kanye nezinhlelo eziningi ezihlukahlukene zokusebenza. Enziwe ngenhlanganisela ye-neodymium, iron, kanye ne-boron, lawa mamagnet aziwa njengezizibuthe eziqinile ezihlala njalo ezitholakala namuhla. Kodwa-ke, lawa mamagnethi adinga ukumbozwa okuyisivikelo noma i-plating ukuze kuqinisekiswe ukuphila kwabo isikhathi eside nokusebenza kahle ezindaweni ezihlukahlukene.

Ukumboza kuyinqubo ebalulekile enqubweni yokukhiqiza kazibuthe be-neodymium. Lesi singqimba esivikelayo sivikela uzibuthe ekugqwaleni, emthelela, nakwezinye izinhlobo zomonakalo ezinganciphisa ngaphambi kwesikhathi uzibuthe wawo. Ngaphandle kokwembozwa okufanele, omazibuthe be-neodymium bangenwa kalula yi-oxidation, ukugqwala, nokuguga komzimba.

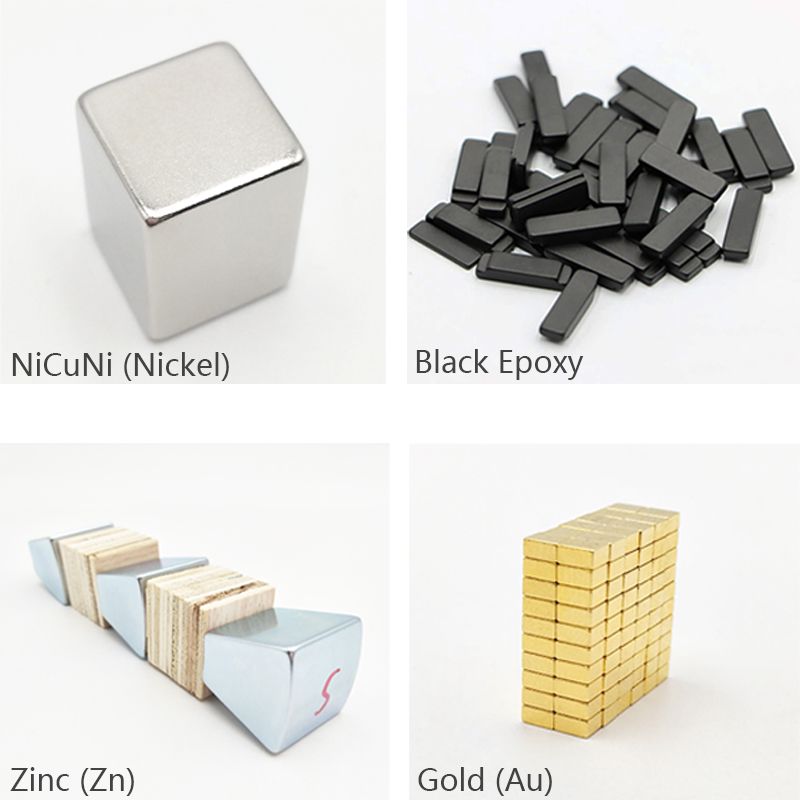

Enye yezingubo ezivame kakhulu zikazibuthe we-neodymium yii-nickel plating. Le nqubo ihilela ukufaka i-electroplating ungqimba oluncane lwe-nickel ebusweni bukazibuthe, okunikeza umgoqo omuhle wokulwa nokugqwala. I-nickel plating ayinhle nje kuphela, kodwa futhi yengeza isendlalelo esengeziwe sokuvikela ezicini zemvelo njengomswakama kanye nomswakama.

Enye i-coating esetshenziswa kabanzi i-epoxy.I-epoxy coating iyisinqumo esithandwayo ngoba inokunamathela okuhle kakhulu futhi imelana namakhemikhali amaningi. Lesi sikhumba se-polymer sisebenza njengesendlalelo esivikelayo, sivikela odonsa kumswakama, umthelela, nokuguga. I-epoxy iphinde ihlinzeke ngokufakwa kwe-insulation kusuka ku-conductivity kagesi, okuyenza ifaneleke izinhlelo zokusebenza ezidinga ukufakwa kukagesi.

Kwezinye izinhlelo zokusebenza ezikhethekile, ozibuthe be-neodymium bangadinga izinketho ezengeziwe zokuhlanganisa. Ngokwesibonelo,galvanizing (I-zinc coating) ithandwa ezindaweni zasolwandle ngenxa yokumelana nokugqwala okuphezulu. Ukwengeza, igolide noma isiliva plating ingasetshenziselwa izinjongo zokuhlobisa noma zobuhle.

Inqubo yokumboza ihilela izinyathelo ezimbalwa zokuqinisekisa ukumbozwa okusebenzayo nokunamathela. Okokuqala, uzibuthe we-neodymium uhlanzwa kahle futhi ucoshwe ukuze kususwe noma yikuphi ukungcola okungase kuvimbele ukunamathela ekunamatheleni. Okulandelayo, umazibuthe uyacwiliswa noma ufafazwe ezintweni zokugqoka ozikhethelayo. Bese belashwa ekushiseni okubangela ukuthi ukunamathela kuqine futhi kubambelele ngokuqinile endaweni yamagnetic.

Ngaphezu kokuthuthukisa ukuqina kukazibuthe, ukunamathela kuphinde kusize ukuvimbela uzibuthe ukuthi ungaphuki noma uqhekeke ngesikhathi sokusetshenziswa. Ungqimba oluncane oluvikelayo lunciphisa ingozi yokulimala okungenzeka ngenxa yomthelela noma ukuphatha okungalungile. Ukwengeza, ukunamathela kwenza uzibuthe kube lula ukuphatha njengoba inikeza indawo ebushelelezi futhi iqeda ubungozi bokuqoshwa noma ukuxebuka.

Lapho ukhetha i-coating yezibuthe ze-neodymium, kubalulekile ukucabangela izidingo ezithile zemvelo kanye nesicelo. Izinto ezifana nezinga lokushisa, umswakama, ukuchayeka kwamakhemikhali, kanye nokuthandwa kobuhle kufanele kucatshangelwe. Ukwengeza, umuntu kufanele aqinisekise ukuthi ukunamathela okukhethiwe akuphazamisi amandla kazibuthe noma ezinye izinto ezifiselekayo zikazibuthe we-neodymium.

Sengiphetha, ukumbozwa kozibuthe be-neodymium kudlala indima ebalulekile ekuthuthukiseni ukusebenza kwabo nokuphila isikhathi eside. Ngokusebenzisa okokuvikela okufana ne-nickel plating noma i-epoxy, lawa mamagnet angavikelwa ekugqwaleni, emthelela, nakwezinye izinhlobo zomonakalo. Ukumbozwa akuthuthukisi nje kuphela ukuqina kukazibuthe kodwa futhi kusiza ukuthuthukisa ubuhle bayo nokufaneleka kwezinhlelo zokusebenza eziningi. Njengoba isidingo sikazibuthe be-neodymium siqhubeka sikhula, ukuthuthukiswa kobuchwepheshe bokunamathela obuthembekile nobusha buhlala bubalulekile ekusebenzeni kwabo okuphelele ezimbonini ezihlukahlukene.

Isikhathi sokuthumela: Oct-27-2023