1. Ozibuthe be-neodymium ngokuvamile benziwa ngengxube eyimpuphu ye-neodymium, i-iron, ne-boron ehlanganiswa ndawonye ngaphansi kokushisa okuphezulu nokucindezela ukwenza umkhiqizo osuphelile.

2. Ingxube yempushana ifakwa esikhunjeni noma esitsheni futhi ishiswe ekushiseni okuphakeme ukuze iqale ukuncibilika futhi ihlanganise.

3. Uma impahla isifinyelele eqophelweni layo lokuncibilika, ibanjelwa kulelizinga lokushisa isikhathi esithile ize iqine ibe yisiqephu esisodwa ngaphandle kwezikhala noma imifantu phakathi kwezinhlayiya.

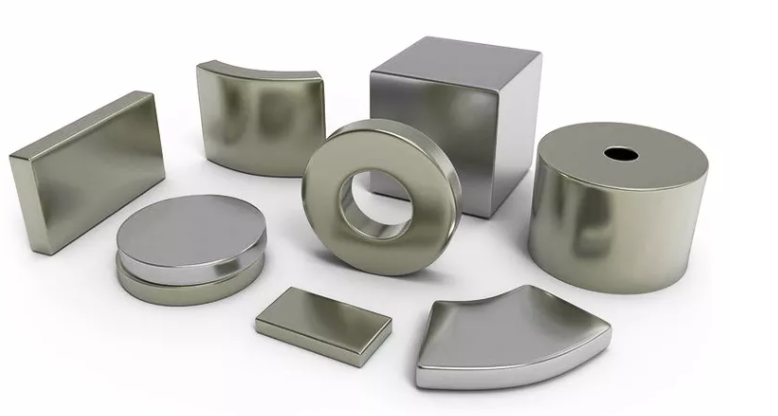

4. Ngemva kokuba ukuqina sekwenzekile, uzibuthe ungenziwa ngomshini ube nesimo nosayizi oyifunayo usebenzisa amathuluzi okusika ahlukahlukene njengemishini yokugaya noma ama-lathes kuye ngokucaciswa kwesicelo.

5. Imiphetho kazibuthe ingabe isipholishwa ishelele uma ifunwa ngaphambi kokuthi igcotshwe ngocwecwe oluyisivikelo njenge-nickel noma i-zinc ngenhloso yokumelana nokugqwala.

Imininingwane eyengeziwe icutshungulwa, sicela ubone ishadi elingezansi elingezansi:

| Cha. | Ukugeleza Kwenqubo | Isinyathelo Sokukhiqiza | Ukusebenza Kwezobuchwepheshe |

| 1 | Ukuhlolwa Kwezinto Ezingavuthiwe | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Ukutholwa kwe-Rohs Ukuhlolwa Kokuqamba Ukuhlaziya Ukuhlanzeka |

| 2 | Ukwelashwa kwangaphambili kwe-Raw Material | 4.Sawing- 5. Drying- 6.Impact Cleaning | I-sawing Iron I-Hot Air Drying Ukuhlanza Okunomthelela |

| 3 | Ukulawula Izithako | 7.Ukulawula Izithako | Isisindo Ukuhlanganisa Hlanganisa i-Raw Material |

| 4 | I-Strip Casting | 8.Vacuumizing-9.Ukuncibilika-10.Ukuphonsa | Ivacuuming Iyancibilika Ukuncibilika Iyasakaza |

| 5 | Ukuncipha kwe-Hydrogen | 11.Pre-treating-12.Vacuumizing-13.Faka iHydrogen | Ukwelashwa kwangaphambili Ivacuuming Diliza ngeHydrojeni |

| 6 | Ukugaya | 14.Ukuphahlazeka-15.Ukugaya-16.Jet Mill-17.Granularity Control | Ukuphahlazeka Ukugaya I-Jet Mill Ukulinganisa Okujwayelekile |

| 7 | Iyacindezela | 18. Isisindo sempushana -19.Pre-pressing - 20.Cindezela -21.Ukucindezela kwe-Isostatic | Isisindo sempushana Ukucindezela ngaphambilini Iyacindezela Ukucindezela kwe-Isostatic |

| 8 | I-Sintering | 22.Vacuumizing- 23.Sintering -24 Ukwelashwa kokushisa | Ivacuuming I-Sintering Ukwelashwa kokushisa |

| 9 | Ukuhlola | 25.BH ijika-26.I-PCT-27.Ukuhlolwa kokuminyana -28.Ukuhlolwa kwe-Roughcast | Isilinganiso samagnetic Ukuhlolwa kwe-coefficient yezinga lokushisa I-PCT Ukulinganiswa Kokuminyana Ukuhlola |

| 10 | Ukwenza imishini | 29.Ukugaya -30.Ucingo Ukusika-31.Inner blade cutting | Ukugaya Ukusika ucingo Ukusika i-internal blade |

| 11 | Ukuhlolwa kwesampula ye-QC | Ukuhlolwa kwesampula ye-32.QC | Ukuhlolwa kwesampula ye-QC |

| 12 | I-Chamfering | 33.Ukukhohlisa | I-Chamfering |

| 13 | I-Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | I-Electroplating Zn Electroplating NICUNI Phosphating noma Chemical Ni |

| 14 | Ukuhlolwa kwe-Coating | 38.Ukujiya-39.I-Corrosion Resistance -40.Ukunamathela-41.-Ukuhlola Ukubekezelela | Ubukhulu Ukumelana Nokugqwala Ukunamathela Ukuhlola Ukubekezelelana |

| 15 | Uzibuthe | 42.Ukuhlola Ngokuphelele- 43.Ukumaka- 44.Ukuhlela/Ukuguquguquka- 45.Ukumaketha | Qedela Ukuhlola Ukumaka Ukuhlela/Ukuguquguquka Ukwenza uzibuthe I-Magnetic Fiux Test |

| 16 | Ukupakisha | 46. Magnetic Flux- 47.Bagging- 48. Ukupakisha | Ukufaka isikhwama Ukupakisha |

Isikhathi sokuthumela: Feb-15-2023